The AMI-400 TPx is a fully automated chemisorption analyser for the characterisation of catalysts.

Based on the Dynamic Flow method, it allows unattended operation from pretreatment to sequences of multiple experiments.

The compact footprint allows the instrument to be easily placed in a fume hood.

Looking for a more in-depth discussion? Contact us at 6744 6645 or

BENEFITS

Wide Temperature Range

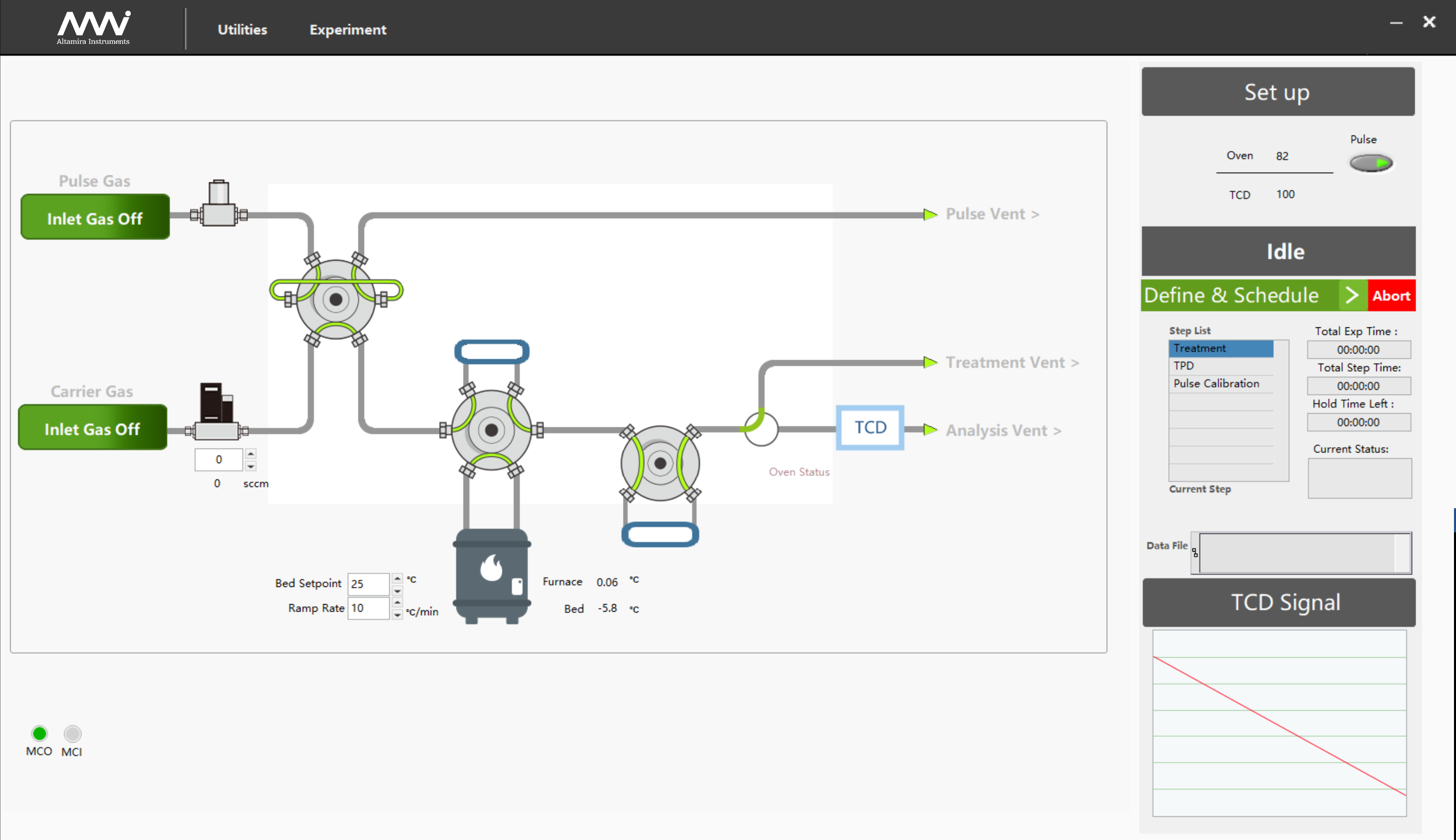

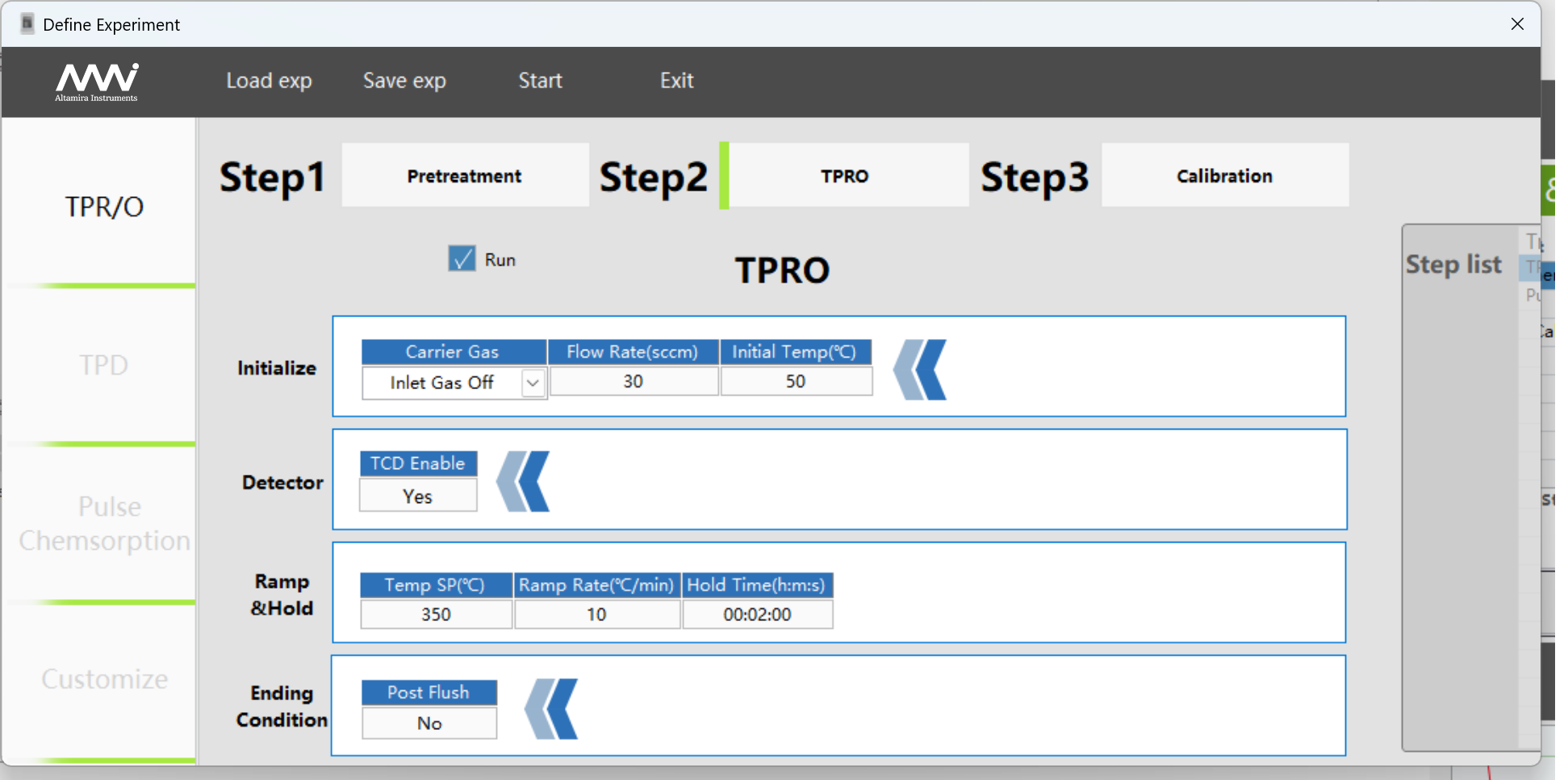

User Friendly Software Interface

Cost Effectiveness

Enjoy a fully automated system that performs all the conventional chemisorption experiments (TPD, TPR, TPO, TPRS, pulse chemisorption & BET specific surface area) at an affordable price.

AMI-300 Series Chemisorption Analyser

The AMI-300 is a fully automated chemisorption analyser that can be used to perform dynamic temperature-programmed experiments to characterise catalytic surface activity.

It can perform pretreatment of catalysts, followed by analysis such as temperature-programmed desorption (TPD), temperature-programmed oxidation (TPO), temperature-programmed reduction (TPR), and temperature-programmed reaction (TPRx). The AMI-300 can also perform pulsed chemisorption and single point BET surface area measurement.

Experimental conditions are fully programmable and up to 99 consecutive treatments and/or analyses procedures can be linked together into one experimental sequence for completely unattended operation.

The sub-ambient option allows the furnace to linearly heat the catalyst sample from -130 to 1,200°C. This is useful for catalysts that are active at sub-ambient temperatures.

The system comes with gas blending capabilities that avoid the need to purchase expensive gas blends for TPR or TPO experiments. An auxiliary gas line allows a gas to be mixed with the carrier gas to provide custom-blended gases. An inline static gas mixer assures homogeneity of the resulting blend.

Optionally, the AMI-300 can be configured for high pressure experiments (AMI-300RHP – 100 bar), sulphur resistance (AMI-300S) or coupled with FTIR for direct measurement of surface active sites and how compounds are bounded to them (AMI-300ir).

The AMI-300 can also be coupled to an auxiliary detector such as a mass spectrometer or FID detector to analyse off gas. Data from auxiliary detectors can be integrated with AMI-300 data in real-time using Direct Data Exchange (DDE) or other Windows protocols.

Single or multi-station configurations for high sample throughput are available.

The 1,000°C furnace is more than adequate to handle most catalyst experiments. It is equipped with a highly linear 4-filament TCD. Up to 99 procedures can be performed sequentially to provide a complete characterisation experiment. The system offers on-board gas blending, GC or MS triggering and single point BET analysis.