In recent years, polymer materials and composites have become increasingly sophisticated and complex, leading to more varied and complicated requirements for their characterisation using thermal analysers. Thermal property analysis shows how the functionality and effectiveness of all sort of materials change when the material is heated or cooled.

The analysis of trace-level samples and the measurement of their constituent parts require high sensitivity for highly precise measurements, and high baseline performance that proves the stability and repeatability of measurements.

In addition, higher baseline performance is required when measuring high-performance polymers and high-performance films, which are used in a wide range of fields in order to precisely measure the thermal properties of the polymers.

Hitachi’s latest series of differential scanning calorimeter (DSC), delivers superior sensitivity with exceptional baseline stability. Two models are offered – NEXTA DSC600 and NEXTA DSC200.

World Class Sensitivity for Trace Level Detection

The NEXTA DSC600 features a proprietary thermopile sensor containing multiple thermocouples. It offers high resolution of 3.0 sec and superior sensitivity 0.1 μW or lower, making it ideal for more advanced material development and failure analysis. The NEXTA DSC200 is a high performance DSC designed to provide the best results for routine quality control. The newly developed gold sensor provides high calorimetric and temperature precision.

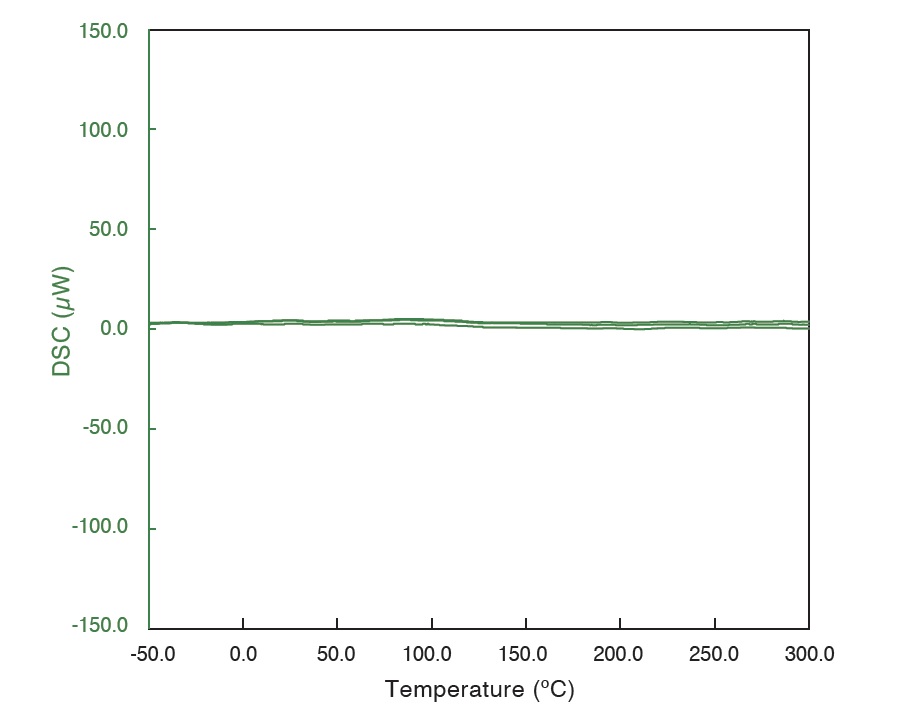

World Class Baseline Stability and Repeatability

Both NEXTA DSC600 and DSC 200 use an advanced heat-flow design in the sensor that allows the heat from the heat sink transferred evenly to the sample and the reference, resulting in high baseline stability. Together with a furnace built with a low-heat-capacity three-layered insulation design, this allows the NEXTA DSC to deliver world-class baseline stability and repeatability of +/- 5 µW.

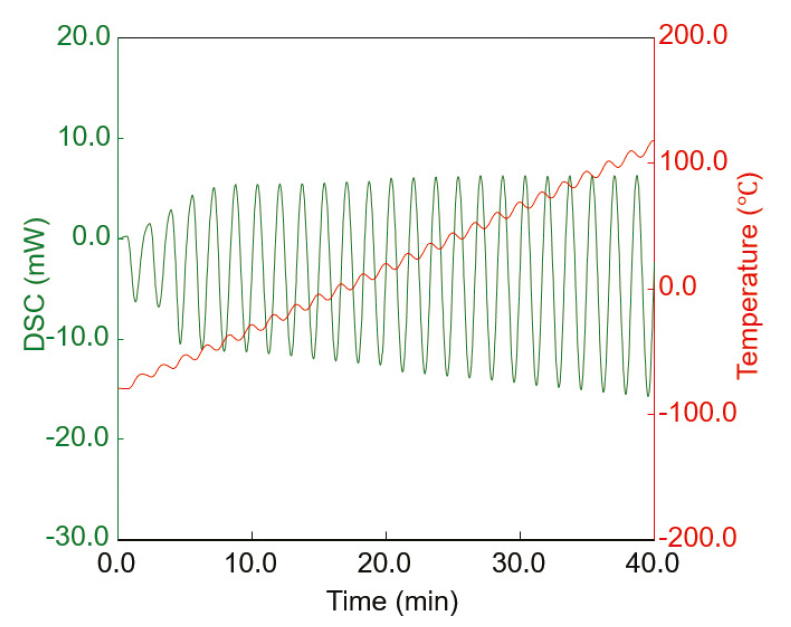

Specific Heat Capacity by Temperature Modulated DSC

Temperature modulated DSC is a measurement technique that separates overlapping phase transitions by adding a sinusoidal variation to a constant rate of temperature increase or decrease. This allows three components – reversing component, nonreversing component and total heat flow – to be determined.

Compared to standard DSC measurements, in cases where the reversing component (glass transition and melting) and nonreversing components (enthalpy relaxation, curing, crystallisation, evaporation, decomposition, etc.) overlap each other, these components can be separated by temperature modulated DSC.

The modulated DSC method can also be used for determining the specific heat capacity (Cp).

Observe Sample Appearance During Thermal Analysis

The Real View Sample Observation Unit allows visual observation of the sample. The viewport (observation window) has a heating mechanism that extends the measurement range from the conventionally observable range of room temperature and above down to the low temperature of -50°C. This enables the user to observe processes such as the crystallization and the glass transition of samples at low temperatures. This offers a unique capability for understanding material behaviour.The digital zoom function allows microscopic features in the sample down to 50 μm to be inspected. The length measurement function allows the changes in dimensions of the sample due to temperature to be measured. The colour analysis function allows colour changes (RGB/MYK/LAB) in the sample to be quantified. The software allows the pictures to be easily matched to the DSC thermogram.