Stability testing is an essential analysis that is used to assess the shelf life of a colloid. Colloidal dispersions that are used for consumer and industrial applications are complex mixtures of multiple ingredients and additives that are dispersed in a fluid by applying mechanical energy (such as mixing, grinding, sonication, ultraturrax).

The first step to obtain a colloid with good stability is to assess whether an optimal dispersion was attained initially.

Particle size distribution is a commonly used parameter to determine whether a desired particle size has been achieved. Conventional particle size analysers require the sample to be diluted either for circulation purposes or to remain within the concentration limits of the technique. Samples would typically be extracted from the process line and analysed in a lab.

The Turbiscan DNS, which is based on Static Multiple Light Scattering (SMLS) technique, provides the ability to measure particle sizes from 10 nm to mm at a concentration range from 10-4 to 95% (v/v). The dispersion can be analysed in its natural condition, without any dilution.

The Turbiscan DNS is an instrument that allows formulation scientists to characterise the entire life cycle of colloids from formulating a dispersion, to testing its stability and to determine its ability to be redispersed. This presents a comprehensive approach to study the stability of a product from formulation to consumption.

Dispersibility

Dispersibility refers to the ability to disperse particles in a liquid to reach spatial uniformity at the desired particle size, as according to ISO/TS 22107:2021.

The Turbiscan DNS offers dual functionalities for the formulator to either:

- Formulate the sample in an external vessel (such as a pilot plant) and circulate the sample to the Turbiscan DNS as an inline particle size analyser in a closed loop system, or;

- Formulate the sample in-situ within the Turbiscan cell using an overhead stirrer.

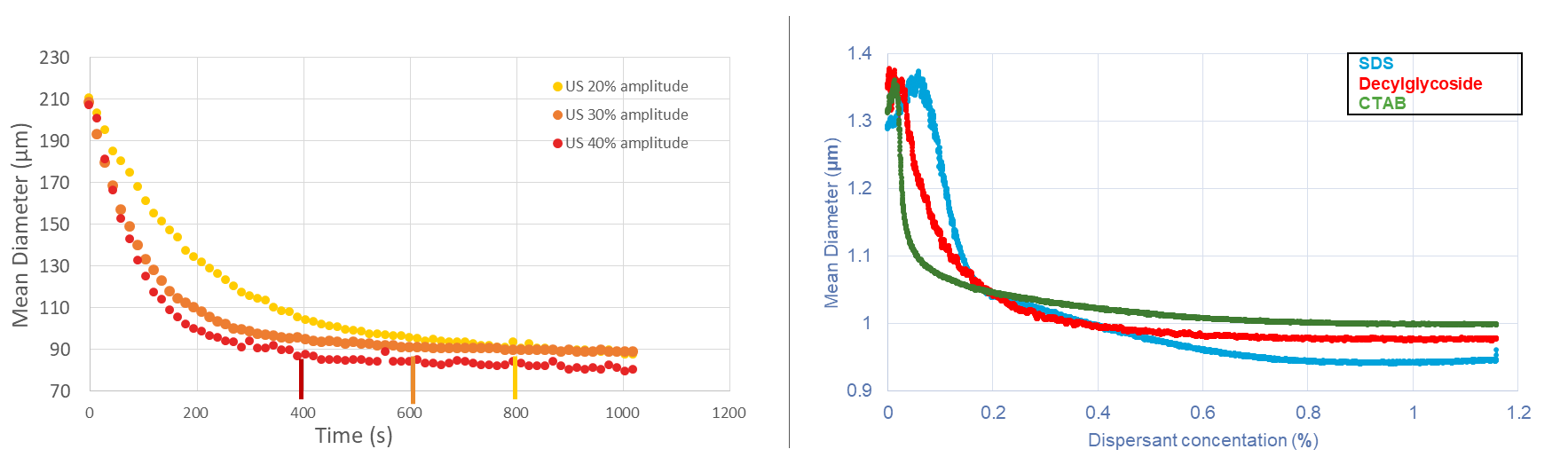

Particle size changes can be detected immediately in response to any changes in process conditions.

It allows the user to determine the optimal processing parameters (such as stirring speed, duration, temperature, type of additive, concentration of ingredients, type of dispersion process) to obtain the desired particle size. It provides valuable data for product formulation and supporting the production team with process optimisation.

Stability

SMLS technique allows the entire sample to be scanned at user selected intervals over a period of time to detect physical changes. The Turbsican series can detect stability issues such as creaming, sedimentation, agglomeration and coalescence of highly concentrated formulations (from foams to pastes). Samples are analysed without dilution or applying mechanical stress, thereby correlating very well with real life observations.

The Turbiscan is up to 1,000 times faster than visual observation and allows early stage destabilisation to be detected and monitored over time to study the kinetics of destabilisation. The migration rate of particles and the rate of concentration change at specific regions of the sample can be analysed.

The Turbiscan Stability Index (TSI) allows the stability of a colloid to be quantified and easily compared with other formulations. This eliminates the subjectivity of conventional visual observation tests where formulations appear similar to the naked eye. It is used in thousands of scientific publications by the academic community for the comparison of stability and shelf life measurement.

The Turbiscan simplifies the job of reformulating products with alternative raw materials for economical and environmental purposes. The stability of products formulated with alternative ingredients can be easily compared against the benchmark commercial product. The optimal concentration of surfactant can be determined.

Redispersibility

Some products that are expected to destabilise during storage have the option to be redispersed prior to application/consumption, such as products that the user to “Shake Well Before Use”. The Turbiscan DNS addresses whether a colloid can regain its initial condition by reapplying mechanical energy. It can be used to determine how easy it is to redisperse a sample, how much time & energy is required to re-homogenise the sample.

Redispersibility is fundamental in regaining the intended colour tone, immune response or taste in applications such as paints, inks, vaccines and beverages, where sedimentation is prevalent.

Foam studies

The Turbiscan DNS can be used to reproducibly generate foam in-situ within the sample cell. The duration of mixing and agitation speed can be adjusted to study the the foamability, opacity and bubble size generated with different additives. The stability of the foam can be assessed to determine the coalescence of air bubbles, foam decay rate and drainage of the liquid.