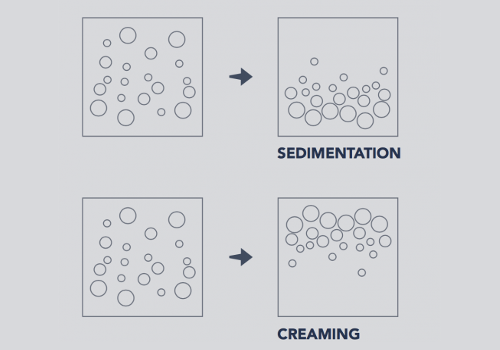

Sedimentation is the process by which solid particles, initially suspended in a liquid phase, settle to the bottom of a container over time. Sedimentation fundamentally occurs because of a difference in density between the two phases. Relatively dense solid particles will naturally sink to the bottom of a less-dense fluid for the same reasons that a stone will sink to the bottom of a lake, or that airborne dust will eventually settle to the ground.

A basic description of sedimentation is given by Stokes’ Law, which considers spherical particles falling through a simple fluid. Stokes’ Law yields an equation for the speed v at which a solid particle will fall out of suspension:

v=(Δρ_p gd^2)/18η

In this equation, Δρ_p is the difference between the densities of the solid and liquid phases, g is the strength of gravity, d is the diameter of the particle in question and η is the viscosity of the liquid phase. This mathematical treatment tells us that sedimentation rate depends on particle size, the viscosity of the liquid phase, and the difference in density between the solid and liquid phases: a stone sinks quickly in water, while construction dust can take minutes or hours to settle depending on particle size.2

It is important to remember, though, that this model is just a first-order approximation.3 Sedimentation in paints, coatings and other real-world products is much more complex, typically involving a concentration of particles of distributed sizes and shapes falling through complex fluids with visco-elastic properties.

Sedimentation in Coatings

The importance of sedimentation varies in different industrial products. In the coatings industry, pigments (non-soluble colorants) and fillers (functional additives) are prone to sedimentation, rendering them practically unusable.

On the plus side, sedimentation is often reversible, which means that solid particles can sometimes be redispersed after they’ve settled. For certain products, this is no problem – many medicines, drinks, and other household products simply instruct the user to “shake well before use.” This is enough to fully redisperse solid material without any significant inconvenience to the end-user.

However, in many coatings and other products, inter-particle bonding means that settled particles can sometimes form hard or rubbery sediment that can’t be redispersed. Even when redispersion is possible, coatings and paints generally require relatively high energy input to achieve this (mechanical stirring, for example).

Sedimentation can be minimized by decreasing the difference in density between solid and liquid phases, decreasing particle size, and increasing the viscosity of the liquid phase. Coatings commonly make use of rheology additives, too, which form 3D networks to support pigments and fillers and prevent them from falling out of suspension. Therefore, controlling sedimentation and redispersion characteristics is essential to the production of high-quality coatings.

Characterizing Sedimentation

In order to limit sedimentation effectively and produce stable products, manufacturers need to be able to accurately characterize these behaviors during product development and manufacturing.

Visual inspection remains the most common method of sedimentation testing in the industry. Undoubtedly easy to implement, visual testing also requires virtually no capital expenditure – however, such methods are invariably subject to guesswork and inaccuracy. As well as being imprecise, the process can also be time-consuming since any variations must be visible to the eye to be detectable.

Turbiscan® technology offers an alternative. Based on Static Multiple Light Scattering (SMLS), Turbiscan stability analyzers provide fast, accurate, and quantified measurements of sedimentation and other destabilization processes in coatings.

Turbiscan® analyzers work by rapidly sending light pulses through a sample at 20 “μm” intervals along its height. A reading head measures backscattering and transmission at each position, with each of these quantities relating to particle concentration and size at that position. By repeating these measurements throughout a specified time interval, Turbiscan® systems give unparalleled insight into sedimentation behavior without any dilution or mechanical stress.

Turbiscan® technology can detect sedimentation up to 200x faster than the naked eye – but, more importantly, it provides a precise, quantified profile of particle distribution along the sample’s height over time. This makes it easy for coatings producers to rapidly obtain useful measurements of sedimentation behavior. For simple comparisons, the Turbiscan Stability Index (TSI) sums all destabilizations into a single value. Many additional parameters can be automatically calculated to give a deeper understanding of sedimentation kinetics within any sample.

These measurements enable manufacturers to objectively determine the best strategy to overcome sedimentation and other destabilizing processes, thus improving coating quality and accelerating the development of new stable coatings.

Looking to find out how to improve coating stability with the Turbiscan? Contact us at 6744 6645 or